Well documented quality initiatives and craftsmanship

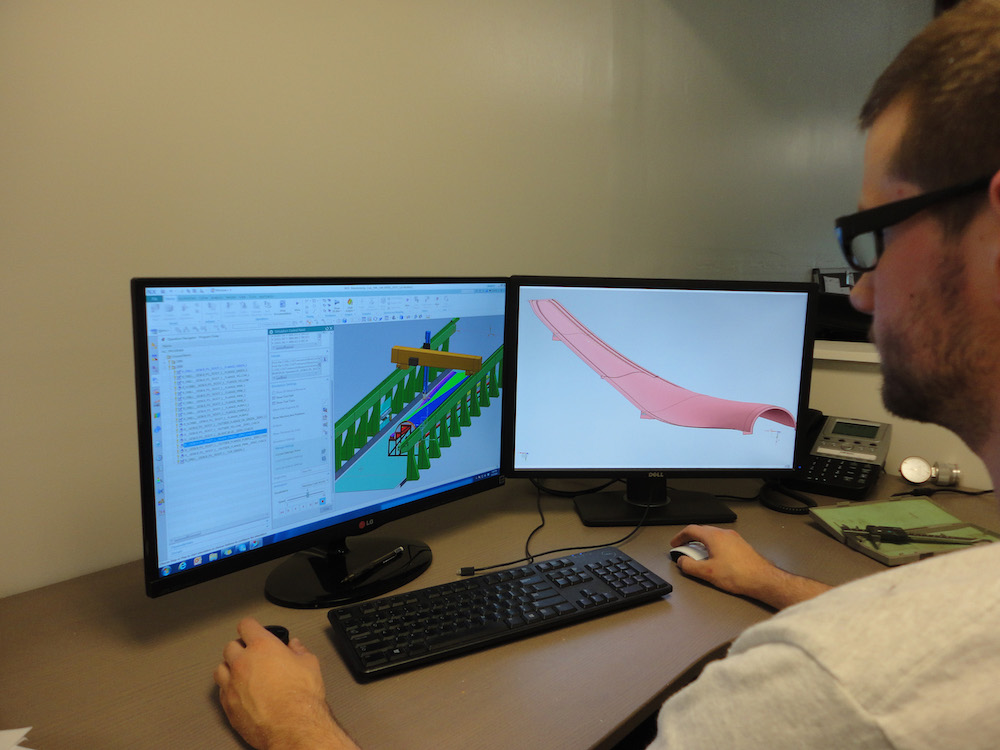

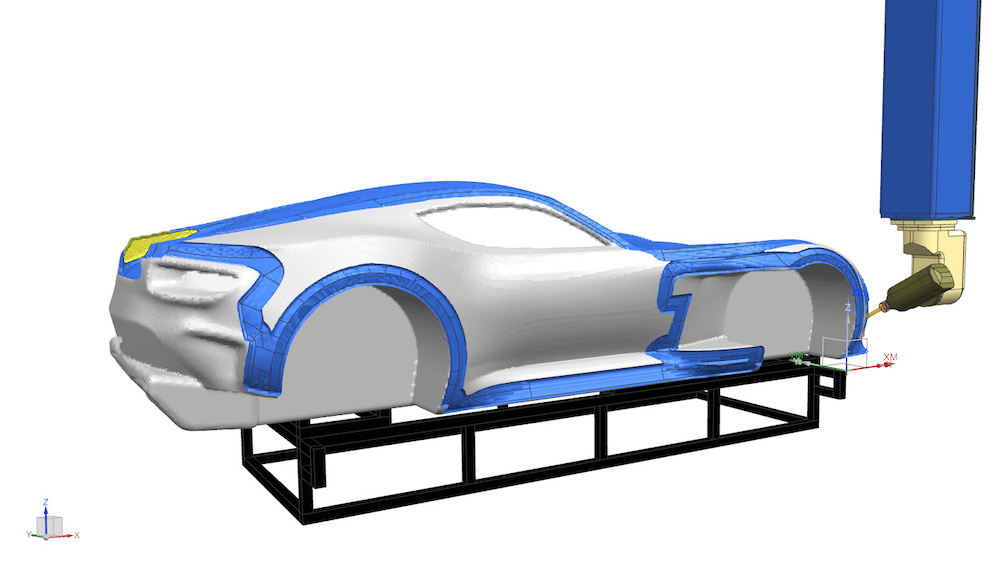

CAD/CAM Expertise

- CAD file management and file control

- Cutting authorization procedures and documents

- Complete 3D simulation of all machined surfaces

- CNC machine calibration checks before every finish cut

- Cutting tool lengths and wear calibrated before every finish cut

- Visual inspection checklist

- Geometry verification and metrology

Composite Processing

- Standard raw material inspection and acceptance procedures

- Document control of raw materials including lot, vat, batch and date of manufacture

- Samples of all resins and seamless modeling paste collected and retained on site for up to 6 months

- Shore-D hardness and Tg testing for modeling paste

- All TDS and MSDS sheets

- Process checklists and shop travelers

Post Cure and Vacuum Integrity

- Thermocouple location map and profile

- Drop test certification report

- Time-stamped HD video