Symmetrix Open House a Success

Friday, September 26 in Bristol, RI was as beautiful of a fall day as you are going to get. The guys in the shop were greeted at 7:30am by the smell of BBQ smoking. At 2pm, work stopped, and we welcomed in friends, family, and finally got to have a little bit of that BBQ.

The goal for the day was to say thank you. Thank you, of course, to the customers who keep the machine running, but also to our vendors who never run out of our most frequently ordered items, and to our families who put up with the Saturdays, holidays, and late nights of work. Without the support of each of them, Symmetrix would never have reached where we are today.

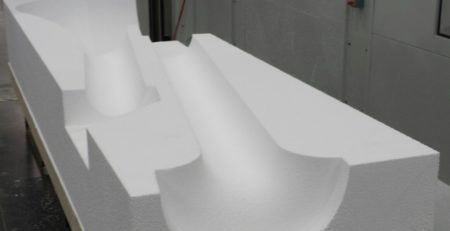

So of course, there were kids running around molds and husbands and wives walking around in our shoes. There were vendors finally seeing what it is we do with their product – Insulation Technology provides Symmetrix with the EPS foam used for the structure of our molds, and a lot of it. The machine had just finished the rough cut on one part of the wind turbine, and the crowd was inspecting the foam and all the little pieces of foam dust left in its wake. Clare Evans, business development at Symmetrix, spoke with Marcia of Insulation Technology.

“I’ve been trying to get you guys to use smaller vacuum bags,” said Marcia, referring to the large bags that hang on the west side of the machine, “but now I’m surprised they’re as small as they are!”

After the guests were able to walk through the inside of the machine, or envelope as we call it, the BBQ was served and the machine was turned on.

The crowd was able to see what we’ve assumed all along – this machine is awesome.

Mark Northey, president of mouldCAM UK, made the trip west to support Symmetrix.

“John Barnitt and his team have invested a huge amount of time, hard work and money in Symmetrix in the last few years and their efforts really have culminated in a world-class operation complete with brand new state of the art CMS 5 axis cnc machine 28m x 6m x 3m and a purpose-built sectional spray booth with heating and extraction. It was a huge pleasure to be present to see this flagship venture up and running and working on 58m wind turbine blade tooling”

TJ Perrotti of US Watercraft and his sons were ecstatic to see everything up and running.

“I stopped by the new Symmetrix shop with my two boys this evening. Though my expectations were high, I walked away even more impressed that I can barely comprehend. The size and speed of the new CNC machine is amazing. Just as impressive is the whole layout of the new shop … fabrication weld area, HUGE dual-sectioned spray booth, and a talented crew to keep everything in smoothly in production. Congratulations to JB and the entire Symmetrix team … this new shop will certainly be an asset to any industry!”

Finally, at 8pm, the crowds had dwindled and the BBQ had been put away. Guests left full and happy – exactly what we had been hoping. It was a great start to what will sure to be an incredible tenure at 115B Broadcommon Road.